Multi-million euro project kicks off: Groundbreaking ceremony for the GEALAN high-bay warehouse in Tanna

Start of construction for the next GEALAN milestone: The groundbreaking ceremony for a fully automated high-bay warehouse took place at the production and logistics site in Tanna. The cost of the construction project has been estimated at around 14 million euros, making it one of the largest single investments in the history of the PVC profile manufacturer. The company is planning to put the new high-bay warehouse into operation in the first half of 2024.

The symbolic ground-breaking ceremony to mark the start of construction was attended by the two GEALAN CEOs, Ivica Maurović and Tino Albert, as well as the Saale-Orla District Chief Executive Thomas Fügmann and Tanna's mayor, Marco Seidel.

After months of intensive planning, the GEALAN CEOs are delighted and proud that the excavators can get back to work in the Kapelle business park. Ivica Maurovic: “This multi-million-euro investment will make GEALAN more effective and more future-proof. It’s also a clear commitment to our location in Tanna and the entire region.” Tino Albert adds: “The investment in our high-bay warehouse will take our logistics to a new level. The opportunities that fully-automated warehousing presents will enable GEALAN to plan, work and deliver even more efficiently.”

The GEALAN high-bay warehouse

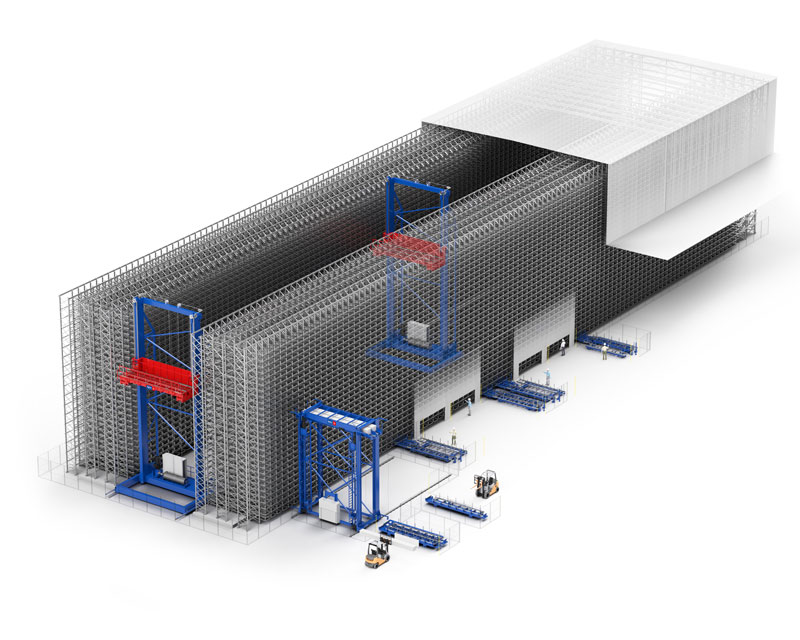

Dimensions: Length 125 m, Height 26 m, Width 22 m.

Number of storage spaces: 5020

Payload per rack: 1700 kg

Output up to: approx. 70 rack changes per hour

The storage and retrieval of goods in the high-bay warehouse is controlled by modern software and carried out mechanically by two so-called rack feeders. This increases the speed and safety of the work steps. The ergonomic design of the picking stations significantly reduces the physical strain on employees.

The advantages of a high-bay warehouse

A high-bay warehouse is a warehouse with shelves from a height of 12 metres. Normally, it offers several thousand pallet storage spaces for the storage of both flat goods and long goods. GEALAN will set up what is known as an automated long goods warehouse at the Tanna site by 2024.

Automatic high-bay and long-goods warehouses make optimal use of the available space: the height ensures that larger volumes can be stored in a minimum of floor space. It also reduces the distances that have to be covered to deliver or transport goods. Due to the full automation, the system is capable of handling even large, heavy and bulky goods quickly and efficiently.

Marc Schenk

18/05/2022

Recent news

The new GEANOVA #4 is here!

Freshly printed or as an online version: with exciting and personal stories, the new 52-page GEALAN magazine once again offers a glimpse behind the scenes of the plastics system provider.

Third gold award in a row for GEALAN's BIM solution

GEALAN's Building Information Modelling data offering once again convinces the jury at the ARCHITECTS' DARLING® Award 2022 and is named the best solution in the construction industry nationwide for the third time in a row, following 2020 and 2021.

From 2.0 to 3.0: New Planersoftware available!

With the Planersoftware 3.0, GEALAN takes the next step when it comes to the technical planning of windows and doors. The new version supports all planning steps with well thought-out, partly new modules, from the selection of profiles to the construction of complete elements (in 2D and 3D). In addition, the Planersoftware 3.0 has been given a more modern look.

Use our manufacturer locator.

Do not miss any news!

I want to receive newsletter "Reference Building of the Month" and GEALAN news via E-Mail (approx. twice a month) - free of charge and terminable at any time.